instruction manual harley rear wheel assembly diagram

The Harley rear wheel assembly is a critical component ensuring stability, performance, and safety. Proper installation and alignment are essential for optimal motorcycle functionality and rider safety.

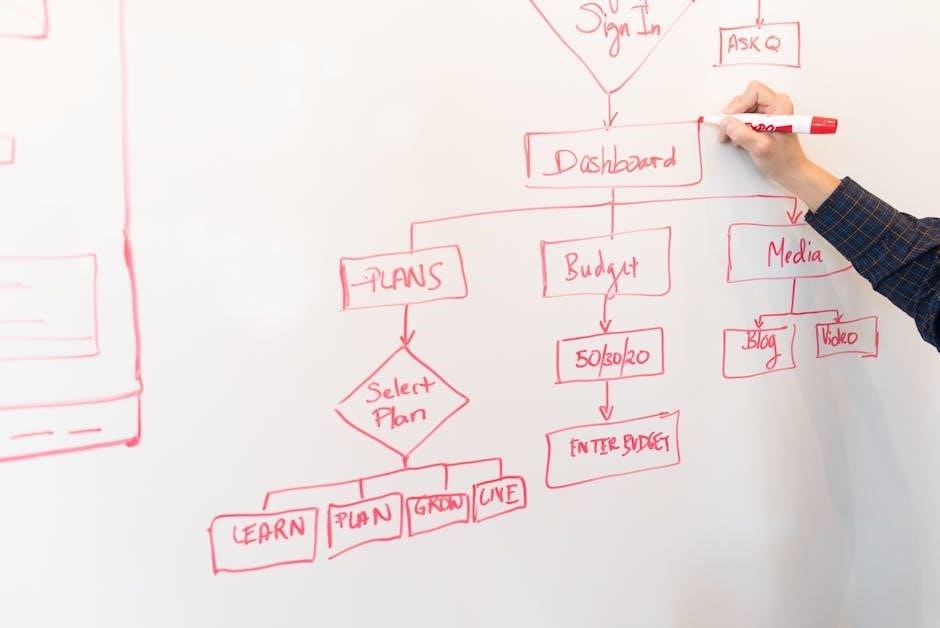

This manual provides a detailed guide, including diagrams, to help you understand and assemble the rear wheel components correctly. Follow the steps carefully to ensure precise installation.

1.1 Importance of Proper Assembly

Proper assembly of the Harley rear wheel is crucial for ensuring rider safety, optimal performance, and longevity of the motorcycle. Incorrect installation can lead to instability, reduced braking efficiency, and potential failure of components while riding.

A well-assembled rear wheel ensures proper alignment of the hub, bearings, and brake rotor, which are essential for smooth operation. Misaligned or loosely fitted parts can cause vibrations, uneven tire wear, and increased risk of accidents.

Following the correct assembly procedures, as outlined in the manual and diagrams, guarantees that all components function harmoniously. This includes ensuring bearings are securely seated, brakes are properly aligned, and the wheel is tightened to the recommended torque specifications.

Skipping steps or using incorrect tools can compromise the integrity of the assembly. Always refer to the official Harley-Davidson diagrams and guidelines to ensure accuracy and safety throughout the process.

1.2 Overview of the Rear Wheel Components

The Harley rear wheel assembly consists of several key components essential for its operation. The hub serves as the central unit, housing the bearings and connecting to the axle. The wheel, available in laced or cast designs, is attached to the hub and includes the rim and spokes for structural integrity.

The brake rotor is mounted on the hub, enabling effective braking, while the pulley or sprocket is integrated for driving the belt or chain. Bearings are critical for smooth rotation, and spacers ensure proper alignment within the frame. Additional components like nuts, washers, and axle bolts secure the assembly in place.

Understanding each part’s role and how they interact is vital for successful assembly. Referencing the exploded diagrams provided in the manual helps visualize the relationships between components, ensuring each piece is installed correctly and securely.

Preparation for Assembly

Gather all tools, materials, and refer to the manual for specific instructions. Ensure a clean, stable workspace and organize components according to the diagram for efficient assembly.

2.1 Tools and Materials Needed

To successfully assemble the Harley rear wheel, you’ll need specific tools and materials. Essential tools include a torque wrench, bearing packer, wheel chocks, and a socket set. Materials required are grease, Loctite, and new bearings if replacing old ones. Safety gear like gloves and goggles is also necessary. Ensure all components like spacers, axles, and nuts are organized; Refer to the manual for exact specifications and quantities. Having a clean, well-lit workspace is crucial for efficiency and accuracy. Double-check the parts list to avoid missing any items. Proper preparation ensures a smooth assembly process and prevents potential issues down the road. Always follow the manufacturer’s recommendations for tools and materials to guarantee a safe and correct installation.

2.2 Understanding the Diagram and Manual

The diagram and manual are indispensable for a successful rear wheel assembly. The manual provides step-by-step instructions, while the diagram offers a visual guide to component locations and relationships. Start by familiarizing yourself with the exploded view, which details each part and its position. Pay attention to labels, symbols, and directional arrows, as they indicate installation orientation and torque specifications. Cross-reference the parts list to ensure all components are accounted for. Understand that the manual may include universal instructions, so focus on sections specific to your Harley model. Misinterpreting the diagram or skipping steps can lead to improper assembly, affecting safety and performance. Use the manual and diagram together to avoid errors and ensure a precise, professional-quality assembly.

Rear Wheel Assembly Process

The rear wheel assembly process involves installing the hub, wheel, bearings, brake rotor, and pulley. Follow precise steps to ensure proper alignment, torque specifications, and functionality for safety and performance.

3.1 Hub Assembly Installation

Installing the hub assembly requires careful attention to detail. Begin by ensuring the hub is clean and free from debris. Align the hub with the axle, ensuring it is properly seated and centered. Use the provided hardware to secure the hub in place, following the torque specifications outlined in the manual. Tighten the bolts in a star pattern to maintain even pressure and prevent warping. Once the hub is securely fastened, inspect the area to ensure there are no gaps or misalignments. Proper installation of the hub assembly is crucial for the overall stability and safety of the motorcycle, as it supports the wheel and braking components.

3.2 Wheel Installation

Once the hub assembly is installed, proceed with mounting the rear wheel. Ensure the wheel is clean and free of debris. For laced wheels, check that all spokes are properly tightened and evenly tensioned. Align the wheel with the hub, ensuring the spacer is correctly positioned. Carefully slide the wheel onto the axle, making sure it is fully seated and centered. Secure the wheel using the axle nut, tightening it to the specified torque value outlined in the manual. Double-check the alignment to ensure the wheel is straight and properly seated. If necessary, use a truing stand to verify wheel alignment and make adjustments as needed. Proper wheel installation is essential for maintaining balance, stability, and safe operation of the motorcycle. Always refer to the diagram for visual guidance and torque specifications to ensure accuracy.

3.3 Bearing Installation and Alignment

Bearing installation is a critical step in the rear wheel assembly process. Begin by ensuring the hub is clean and free of debris. Apply a thin layer of high-quality grease to the bearing surfaces. Carefully place the bearings into their respective grooves, ensuring they are fully seated and aligned properly. Use a bearing installer tool to gently tap them into position. Once installed, check the bearings for proper alignment by spinning the wheel and ensuring it rotates smoothly without wobble. If misalignment is detected, adjust the bearings accordingly. Tighten all bearing retention hardware to the specified torque value, as outlined in the manual. Proper bearing installation and alignment are essential for maintaining wheel stability, reducing wear, and ensuring safe operation. Always refer to the diagram for visual confirmation of correct bearing placement and alignment.

3.4 Brake Rotor and Pulley Installation

After the wheel and bearings are installed, proceed with the brake rotor and pulley installation. Begin by cleaning the hub surface to ensure a secure fit. Align the brake rotor with the hub, ensuring the mounting holes are properly seated. Secure the rotor using the provided bolts, tightening them in a star pattern to avoid warping. Once the rotor is in place, install the pulley, ensuring it is correctly aligned with the drive system. Tighten the pulley bolts to the specified torque value, as indicated in the manual. Finally, inspect the brake rotor and pulley for proper alignment and function. Ensure there is no wobble or misalignment, as this could affect braking performance and drivetrain efficiency. Refer to the diagram for precise visual guidance during installation.

Troubleshooting Common Issues

During or after rear wheel assembly, several issues may arise. One common problem is wheel wobble, often caused by improper alignment or loose spokes. To fix this, ensure all spokes are evenly tightened and check the hub for misalignment. Another issue is noise from the bearings or pulley, which may indicate improper installation or lack of lubrication. Inspect the bearings and pulley, ensuring they are correctly seated and lubricated. If the brake rotor is misaligned, it can lead to poor braking performance. Refer to the diagram to realign the rotor properly. Lastly, if the pulley is loose, tighten the bolts to the specified torque. Addressing these issues promptly ensures optimal performance and safety.

After completing the rear wheel assembly, perform a thorough inspection to ensure all components are correctly installed and functioning properly. Check the tightness of all bolts and nuts, ensuring they meet the torque specifications outlined in the manual. Inspect the wheel for proper alignment and balance, and verify that the brake rotor is securely attached and aligned. Spin the wheel to ensure smooth rotation without wobbling or noise. Test the brakes to confirm they engage evenly and effectively. Finally, review the exploded diagram to ensure no parts were missed or improperly installed. Once all checks are passed, the rear wheel assembly is ready for safe use, providing optimal performance and reliability for your Harley-Davidson motorcycle.